Munson Machinery has introduced the Model SCC-15-SS Screen Classifying Cutter with a double-width infeed hopper that accommodates conveyor-feeding of irregular shapes and sizes of hard, soft and/or fibrous materials by gravity.

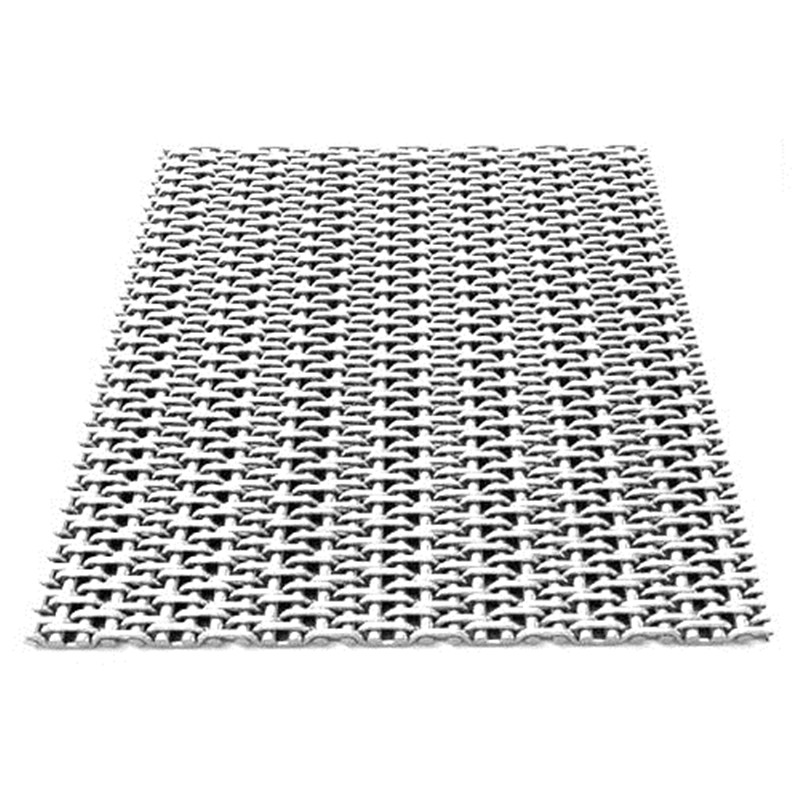

The 30-in. (76 cm) wide hopper funnels materials into a 15-in. (38 cm) wide throat positioned over an 11-in. (279 mm) diameter solid-mass rotor containing staggered parallelograms, each of which holds two, half-inch (12.7 mm) wide cutter tips that are designed to be easy to replace using one machine screw. Stainless Woven Wire Mesh

As material enters the infeed chute, it is subjected to successive mechanical shearing against bed knives until small enough to pass through bedscreen apertures, resulting in uniform size reduction from coarse down to 20 mesh with minimal fines or heat generation, at high rates with reduced energy use.

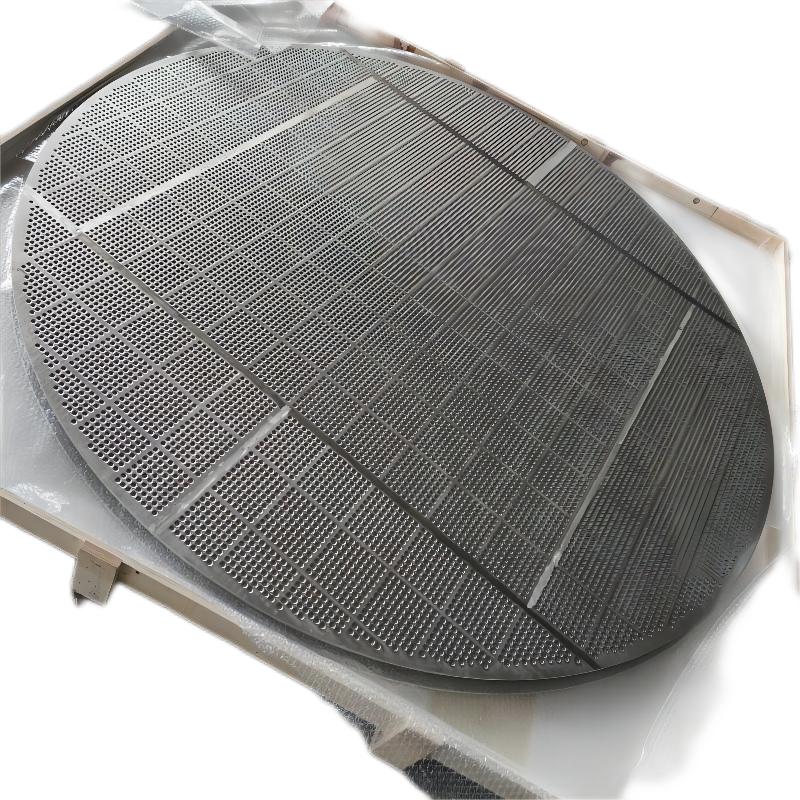

Bedscreen perforations range from 1/32 to 2 in. (0.79 to 51 mm) in diameter and up to 3 in. (76 mm) square. The shaft rotates at 30 to 3600 RPM, producing up to 500 ft.3/h (14 m3/h) of sized product, depending on application.

The cutter is fabricated with material contact surfaces of #304 stainless steel, and is powered by an optional 7.5 HP (5.6 kW) gear motor drive.

Commonly reduced materials include bulk foods, spices, sugar cane and hemp stalks.

Also offered are SCC models with 11-in. (279 mm) diameter rotors and throat widths of 10 in. (254 mm), 30 in. (763 mm), 48 in. (1219 mm), 60 in. (1524 mm) or 72 in. (1829 mm), in addition to Mini Cutters for low-volume and laboratory applications, and Magnum Cutters with 18-in. (457 mm) diameter rotors for higher production rates. All are offered in industrial, abrasion resistant and food-grade construction.

You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

This provocative multifaceted presentation will delve into the technology affecting food manufacturing and how companies have put it to work for them. More importantly, this session will share how to implement it and make it work for you.

Building a new state-of-the-art Fresh Pack Vegetable Manufacturing Facility that would efficiently meet the evolving external regulatory landscape for frozen vegetables as the FDA evolves the industry to more of a ready-to-eat (RTE) standard which requires additional food safety-related design and practices.

Combining scientific depth with practical usefulness, this book serves as a tool for graduate students as well as practicing food engineers, technologists and researchers looking for the latest information on transformation and preservation processes as well as process control and plant hygiene topics.

Copyright ©2023. All Rights Reserved BNP Media.

Sintered Wire Mesh Filter Design, CMS, Hosting & Web Development :: ePublishing